SZ CnAuto automation equipment Co., Ltd.

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

Specializing in the production of automatic\precision\high speed dispenser manufacturers

Hot Tel:

18929475867

TEL:

18929475867

深圳中制自動化設備有限公司

Email:jerry@prcrobot.net

QQ:a :

ADD:東莞市塘廈鎮石潭浦大逕路62號

作者:馬交易???日期:2019-09-10 18:44???瀏覽:

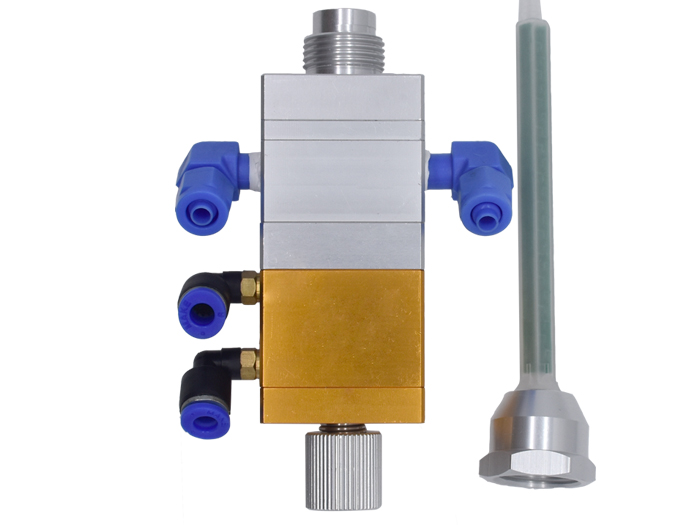

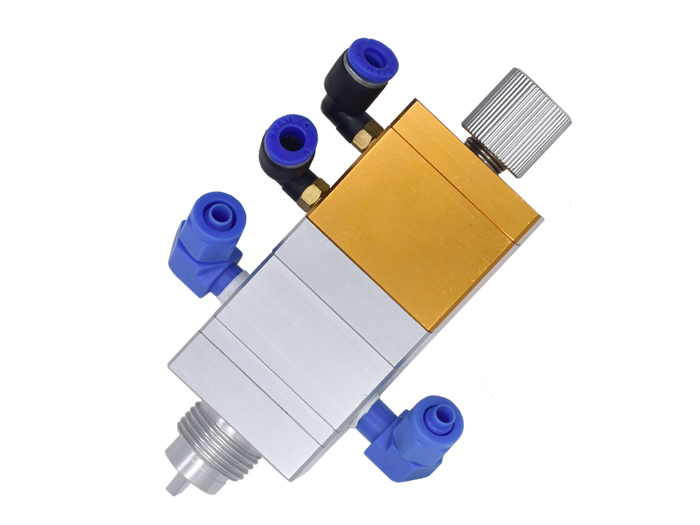

This often happens after the valve closes. 95% of the problem is caused by the use of needle caliber children. Too small needle will affect the flow of liquid, leading to the problem of internal back pressure, resulting in the natural dropping of glue soon after the valve closes. Too small needle will directly affect the role of the exhaust bubble of the glue filling valve. Replacing larger needles will solve this problem. The second solution is to use tapered oblique needle to reduce the back pressure of the rubber valve and improve the fluidity of the fluid.

This often happens after the valve closes. 95% of the problem is caused by the use of needle caliber children. Too small needle will affect the flow of liquid, leading to the problem of internal back pressure, resulting in the natural dropping of glue soon after the valve closes. Too small needle will directly affect the role of the exhaust bubble of the glue filling valve. Replacing larger needles will solve this problem. The second solution is to use tapered oblique needle to reduce the back pressure of the rubber valve and improve the fluidity of the fluid.